Product Description

cABS-GF25 is a reinforced ABS filament featuring a unique skin-core composition. Inside, it comprises ABS blended with 25% glass fiber for reinforcement, while the exterior is made of pure ABS resin known for strong adhesion.

During printing, the polymer fluid remains laminar, preserving the skin-core structure through the extrusion process. This special design ensures low shrinkage, high warpage resistance, exceptional mechanical strength, and improved layer bonding compared to typical fiber-reinforced materials. It eliminates the common issue of reduced layer adhesion seen in other fiber-reinforced filaments. Plus, cABS-GF25 prints have a smooth matte finish without any surface fiber residue.

Advantages over typical fiber-reinforced materials:

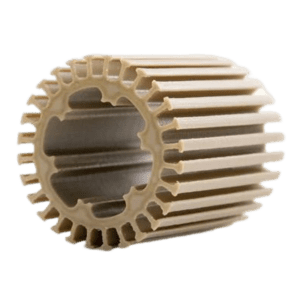

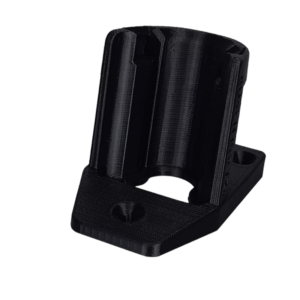

Enhanced Mechanical Properties: The combination of ABS with 25% glass fiber reinforcement significantly improves the filament’s strength, rigidity, and impact resistance.

Superior Layer Adhesion: cABS-GF25’s unique skin-core structure enhances the bonding between printed layers, addressing a common weakness in traditional fiber-reinforced materials which can suffer from reduced layer adhesion.

Reduced Shrinkage and Warpage: The filament’s design minimizes shrinkage and warpage, enabling the production of larger and more dimensionally accurate parts without the deformation issues associated with standard fiber-reinforced materials.

Improved Aesthetic Finish: Unlike typical fiber-reinforced filaments, cABS-GF25 prints feature a bright matte texture without surface fiber residue, offering a more pleasing appearance suitable for both functional and display pieces.

Stable Printing Process: The laminar flow of the polymer fluid during printing helps maintain the integrity of the skin-core structure, ensuring consistent quality and performance throughout the printing process.

Versatility in Applications: Due to its robust mechanical and aesthetic properties, cABS-GF25 is suitable for a wide range of applications, from functional prototypes to end-use parts that require durability and a high-quality finish.

| Recommended Printing Settings | Physical Properties | Mechanical Properties |

| Drying Setting | 70℃,4-6h | Desity | 1.15g/cm³ | Tensile Strength | 48.48±0.61 Mpa |

| Nozzle Temperature | 250~270℃ | Heat Deflection Temp. | 87℃ | Bending Modulus | 3531.71±75.79 MPa |

| Bed Temperature | 100~110℃ | Melting Temperature | 250℃ | Bending Strength | 78.80±1.26 MPa |

| Printing Speed | 30-120mm/s | Melt flow Index | 4.2g/10min | Notched Impact Strength | 8.91±0.63 KJ/㎡ |

Related