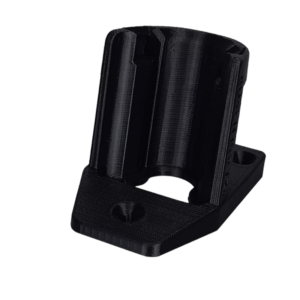

Product Description

The cPA-CF25 filament, enriched with 25% carbon fiber and a distinct skin-core structure, is perfect for 3D printing slender walls with robust mechanical strength. Its outer “skin” layer, made of a special resin, ensures excellent layer adhesion, while the core is reinforced with chopped fibers for added toughness. Leveraging laminar flow during printing, it preserves its structural integrity, boosting interlayer bonding especially along the Z-axis in FDM printing. With the carbon fiber reinforcement, it not only amplifies the mechanical strength and heat resistance of prints but also significantly increases their durability.

Optimized Layer Adhesion: The “skin” layer, made from a modified resin, significantly strengthens the bond between layers, ensuring durable and reliable prints.

Enhanced Core Strength: At its heart, the filament features a reinforced resin rich in chopped fibers, providing the backbone for its superior mechanical properties.

Stable Printing Dynamics: Leveraging the laminar flow characteristic of polymer fluids, cPA-CF25 maintains its unique skin-core integrity throughout the printing process, enhancing stability and quality.

Superior Mechanical and Heat Resistance: The integration of 25% chopped carbon fiber not only bolsters the mechanical strength of your prints but also improves their resistance to high temperatures, yielding parts that are both strong and enduring.

| Recommended Printing Settings | Physical Properties | Mechanical Properties | |||

|---|---|---|---|---|---|

| Drying Setting | 80-100℃,4-6h | Desity | 1.23g/cm³ | Tensile Strength(X-Y)(Annealed) | 118.19 ± 3.82 Mpa |

| Printing and keeping container's humidity | <15% RH | Water absorption | 1.09 % | Breaking Elongation Rate(X-Y)(Annealed) | 1.62 ± 0.12 % |

| Nozzle Temperature | 300~340℃ | Heat Deflection Temp. | 124.2-196.9℃ | Bending Modulus(X-Y)(Annealed) | 9214.34 ± 249.80 MPa |

| Bed Temperature | 70~80℃ | Melting Temperature | 237℃ | Bending Strength(X-Y)(Annealed) | 184.19 ± 5.73 MPa |

| Printing Speed | 30-120mm/s | Melt flow Index | 4.2g/10min | Notched Impact Strength(X-Y)(Annealed) | 7.29 ± 0.76 KJ/㎡ |