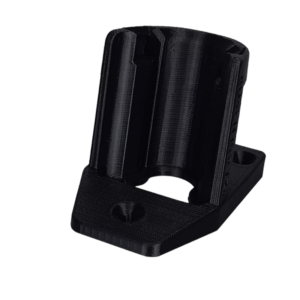

Product Description

Discover the power of PAHT-CF, expertly designed to revolutionize your FDM 3D printing experience. Crafted with cutting-edge high-temperature nylon, this material boasts a remarkable combination of attributes: exceptional strength, minimal moisture absorption, superior wear resistance, outstanding chemical resilience, and remarkable heat endurance.

Our specially formulated nylon material forms the foundation of PAHT-CF, ensuring unparalleled results for your printing projects. Say goodbye to concerns about moisture affecting your prints, as PAHT-CF’s low moisture absorption guarantees pristine outcomes every time.

Experience the freedom of high-strength prints that endure, showcasing robust wear resistance and impressive chemical tolerance. Plus, with its impressive heat resistance, PAHT-CF stands strong even in challenging environments.

Say farewell to the frustrations of warping, shrinking, and unstable dimensions during the printing process. PAHT-CF’s advanced formulation ensures impeccable dimensional stability, providing a seamless printing experience from start to finish.

But that’s not all – our innovation extends beyond the material itself. Pair PAHT-CF with our user-friendly, easy-to-peel support material for an unbeatable solution to enhance the quality of complex model support surfaces. Transform intricate designs into flawlessly molded masterpieces effortlessly.

Elevate your FDM 3D printing to new heights with PAHT-CF. Experience the future of precision, strength, and reliability in every print. Choose PAHT-CF today for printing excellence that knows no bounds.

The Advatages:

* Intelligent Fiber Reinforcement Technology:

The dispersion and distribution of the reinforced fibers in the material matrix are controlled by the production process, so that the reinforced fibers form a network skeleton structure in the material and bear most of the load transmitted by the material matrix. We use SFR technology to greatly improve the mechanical properties and heat resistance of the material, and release the internal stress in the printing process by strengthening the fiber network structure, and the printed piece has good dimensional stability and no warpage problem.

* Ultra low humidity Sensitivity:

Base material uses high temperature nylon, the saturated moisture absorption rate is only one tenth of that of ordinary PA6, completely solve the defects of nylon material mechanical properties and dimensional stability change greatly before and after absorption.

* Super wear resistance:

Ultra PA-CFhas low friction coefficient, self-lubrication and excellent wear resistance. Easy to implement all kinds of high strength gear and wear requirements of industrial applications.

Quality:

We have complete control over the manufacturing process and are able to ensure consistent quality for every spool.

Diameter Tolerance:

Variable diameter can cause big problems in your 3D printer. We use a multi-axis laser measurement system to control our filament diameter and ovality in real time during production.

Packing Information:

A full 1kg (2.2lbs) of Standard PLA plastic filament arrives on a durable plastic reel and is vacuum sealed with a desiccant packet to keep out any moisture.

Test Printing:

24/7 printing test to ensure continuous printing stability. Our test lab features multiple brands of 3D printers including Raise3D, MakerBot, FlashForge, and more.

Other suggestions:

1. Nylon material is very easy to absorb moisture in the environment, and there will be wire drawing, extrusion bubbles and other phenomena after hygroscopic printing, reducing the quality of printing. It is recommended that you put the wire into the drying box immediately after opening the package (humidity controlled below 15%) for printing. Unused wires should be put back into original packaging bags and sealed for storage.

2. After the material is damp, there will be an increase in printing wire drawing, extrusion bubbles, rough printing surface quality and other phenomena. Please dry the wire in the oven at 80-100℃ for 4-6h to restore the printing quality.

3. It is recommended to choose hardened steel and above grade nozzle, which can effectively improve the printing quality. It is recommended that the thickness of the heating block is not less than 12mm.

4. After printing, the printed pieces can be annealed to further improve the strength of the printed pieces. Conditions of return: it can be taken out after placed at 80-100℃ for 4-8 hours.

| Recommended Printing Settings | Physical Properties | Mechanical Properties | |||

|---|---|---|---|---|---|

| Drying Setting | 100-120℃,4-6h | Desity | 1.2g/cm³ | Tensile Strength(Annealed) | 95.53±3.62 Mpa |

| Printing and keeping container's humidity | <15% RH | Water absorption | 1.37 % | Breaking Elongation Rate(Annealed) | 1.52±0.11 % |

| Nozzle Temperature | 300~320℃ | Heat Deflection Temp. | 117.5-190.7℃ | Bending Modulus(Annealed) | 7098.40±440.49 MPa |

| Bed Temperature | 70~90℃ | Melting Temperature | 237℃ | Bending Strength(Annealed) | 141.82±4.34 MPa |

| Printing Speed | 30-120mm/s | Melt flow Index | 3.4g/10min | Notched Impact Strength(Annealed) | 5.62±0.67 KJ/㎡ |