Product Description

PEEK-CF combines the foundational benefits of Polyether Ether Ketone (PEEK) with the advanced technology of carbon fiber reinforcement. This innovative material harnesses PEEK’s renowned high-temperature stability and mechanical excellence, alongside the lightweight and strength attributes of carbon fiber.

Distinct Advantages:

Enhanced Mechanical Properties: The addition of carbon fiber to PEEK significantly boosts its mechanical strength, making it tougher and more durable than most 3D printing materials.

High-Temperature Resistance: PEEK-CF stands out for its exceptional ability to maintain structural integrity and performance at high temperatures, far surpassing the capabilities of standard thermoplastics.

Superior Chemical Resistance: This material exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents, making it suitable for challenging environments.

Improved Wear Resistance: The inherent toughness of PEEK-CF contributes to its enhanced wear resistance, ideal for creating parts that endure high stress and friction.

Lightweight: Despite its strength and durability, PEEK-CF remains lightweight due to its carbon fiber reinforcement, essential for applications where every gram counts, such as aerospace and automotive engineering.

Outstanding Dimensional Stability: PEEK-CF exhibits minimal shrinkage and warping during the printing process, ensuring precise and reliable dimensional stability for intricate designs and tight tolerances.

Versatility: Its robust properties make PEEK-CF adaptable across various demanding applications, from aerospace components and automotive parts to medical devices and industrial machinery.

Key Applications of PEEK-CF:

Aerospace and Aviation: Utilized for manufacturing lightweight yet strong components such as brackets, housings, and aero-engine parts that benefit from PEEK-CF’s superior thermal and chemical resistance.

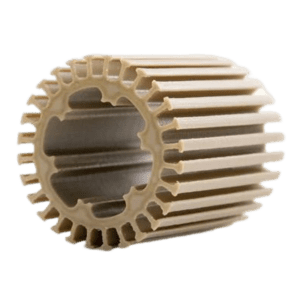

Automotive: Ideal for producing high-performance automotive parts, including gears, pumps, bushings, and connectors, which require a high strength-to-weight ratio and resistance to harsh environments.

Medical Devices: Used in creating custom orthopedic implants, surgical instruments, and dental devices, capitalizing on its biocompatibility, sterilizability, and chemical resistance.

Oil and Gas Industry: Suitable for fabricating seals, gaskets, and pipes exposed to extreme conditions, leveraging PEEK-CF’s resistance to chemicals and high temperatures.

Electronics: Applied in electronic components like connectors, insulators, and enclosures that must withstand high operating temperatures and mechanical stress.

Industrial Machinery: PEEK-CF is used in producing high-strength machine parts, such as bearings, piston parts, and valve components, that operate under high stress and temperature conditions.

Robotics: Essential for crafting robust and lightweight parts for robots and drones, where PEEK-CF’s mechanical properties ensure durability and efficiency.

Research and Development: Favoured for prototyping and experimental designs in R&D projects, enabling the exploration of innovative solutions across scientific and engineering disciplines.

High-Performance Sports Equipment: Used in making durable, lightweight components for sports equipment, offering athletes a competitive edge.

PEEK-CF’s blend of lightweight, strength, thermal stability, and chemical resistance opens new possibilities for designing and manufacturing advanced components that were previously unachievable with traditional materials.