Product Description

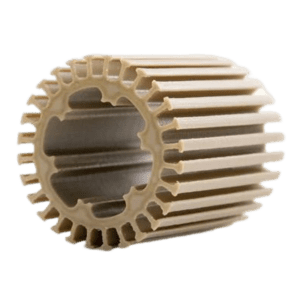

Explore the Unmatched Durability of PEI Ultem1010 for 3D Printing

Discover the superior qualities of PEI Ultem1010, a polyetherimide plastic optimized for 3D printing that delivers unparalleled heat resistance, exceptional strength, and toughness. Known for its excellent flame retardancy and comprehensive chemical resistance, PEI Ultem1010 is the material of choice for demanding applications.

Key Highlights of PEI Ultem1010:

Supreme Heat Resistance: Withstanding temperatures up to 200℃ without deformation, making it ideal for high-temperature applications.

Robust Physical Properties: Offers high tensile and bending strength alongside remarkable impact resistance, ensuring durability and reliability.

Chemical Resistance: Maintains integrity against gasoline, various hydrocarbon solvents, and even mild acids and bases, providing versatility across applications.

Advanced Flame Retardancy: Achieves a UL94 V-0 flame retardant rating, ensuring safety in critical environments.

Versatile Applications: Perfect for food and pharmaceutical packaging, medical device manufacturing, conceptual modeling, functional prototyping, and a vast array of end-use components.

Applications:

PEI Ultem1010, with its exceptional properties, finds widespread use across a multitude of industries and applications. Some of the key areas where it is particularly valued include:

Aerospace and Aviation: Utilized for parts that demand high strength and heat resistance, such as interior cabin components, ducting, and thermal insulation covers.

Automotive: Applied in under-the-hood components, electrical connectors, and components requiring dimensional stability and resistance to automotive fluids.

Electronics: Used for making high-performance electrical insulators, printed circuit boards, and connectors due to its excellent electrical insulation properties and flame retardancy.

Medical Devices: Suitable for surgical instruments, sterilizable trays, and medical device components due to its biocompatibility and ability to withstand repeated sterilization processes.

Food Processing and Packaging: Employed in food processing equipment and pharmaceutical packaging because of its compliance with food contact regulations and resistance to hot water and steam cleaning.

Industrial Machinery: Used in manufacturing jigs, fixtures, and gears that require high strength, stiffness, and thermal stability.

Consumer Electronics: For parts like enclosures that must be robust, heat resistant, and flame retardant while maintaining a high-quality surface appearance.

Research and Development: In R&D projects where materials with exceptional mechanical, thermal, and chemical properties are required for prototyping and testing under extreme conditions.

The unique combination of high-temperature resistance, strength, chemical resistance, and flame retardancy makes PEI Ultem1010 a preferred material in these demanding applications, underscoring its versatility and reliability in critical environments.

Related