Product Description

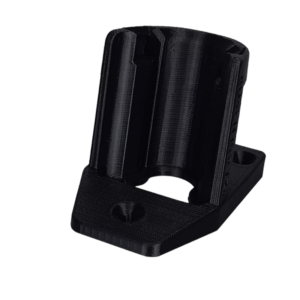

PET-CF 3D Printing Filament, 15% chopped carbon fiber reinforced Polyethylene Terephthalate FDM material, specially developed for FDM 3D printing process, and its substrate material is PET engineering plastic with low moisture absorption, high strength, creep resistance, excellent chemical resistance, and high heat resistance. With good dimensional stability, no warpage no shrinkage, and no smell, no heating chamber is required during the printing process. It can be used with S-PET Quick-Remove Support Material to solve the problem of poor molding effect of supporting the surface of a complex model.

Intelligent fiber reinforcement technology

Controlling the dispersion and distribution of chopped carbon fibers within the material matrix during the extrusion process, the fibers form a mesh skeleton structure within the material and bear most of the load transferred by the material matrix. Smart Fiber Reinforced Technology greatly improves the mechanical properties and heat resistance of the material, and releases the internal stress during the printing process through the fiber mesh structure, resulting in good dimensional stability of the printed part and no warpage.

Low creep

The molecular chain structure of PET is highly regular and has a rigid benzene ring structure so PET has better mechanical properties and less deformation under long-term load. Compared with PA and PC materials, PET has better creep resistance.

Carbon Fiber Reinforcement

PET-CF 3D Printing Filament is enhanced with 15% carbon fiber, significantly boosting its strength, stiffness, and impact resistance for durable and reliable prints.

Creep Resistance

Maintains shape and integrity under continuous stress, ideal for functional and load-bearing parts.

Dimensional Stability

Provides precise, warp-free, and shrink-free prints, ensuring accuracy and reliability.

More about the product

No Heating Chamber Required:Prints effectively without the need for a heated chamber, simplifying the printing process and saving energy.

Low Moisture Absorption:The filament’s low moisture absorption ensures consistent quality and reduces the risk of print failures due to filament degradation.

High Heat Resistance:PET-CF can withstand high temperatures, making it ideal for parts exposed to heat.

| Material Properties | ||

|---|---|---|

| Property | Testing method | Typical value |

| Density | ISO 1183 | 1.30 g/cm³ |

| Water absorption | ISO 62: Method 1 | 0.50% |

| Melting Temperature | ISO 11357 | 251 °C |

| Melt index | 270 °C, 2.16 kg | 4.7 |

| Determination of temperature | ISO 75: Method A | 112.1 °C (1.80MPa) |

| Tensile strength(X-Y) | ISO 527 | 87.41 ± 3.57 MPa |

| Young’s modulus(X-Y) | 6025.53 ± 355.46 MPa | |

| Elongation at break (X-Y) | 1.99 ± 0.18 % | |

| Bending strength (X-Y) | ISO 178 | 122.69 ± 5.19 MPa |

| Bending modulus (X-Y) | 5313.21 ± 197.89 MPa | |

| Charpy impact strength (X-Y) | ISO 179 | 5.57 ± 0.58 KJ/m2 |

| Tensile strength (Z) | ISO 527 | 33.61 ± 1.74 MPa |

| Young’s modulus (Z) | 3194.73 ± 74.46 MPa | |

| Elongation at break (Z) | 1.25 ± 0.09 % |

| Recommended Printing Settings | |

|---|---|

| Nozzle Temperature | 280-320 °C |

| Recommended Nozzle Diameter | 0.4-1.0 mm |

| Recommended build plate | PEI or Coating with PVP glue |

| Build plate temperature | 60-80 °C |

| Raft separation distance | 0.08-0.12 mm |

| Cooling fan speed | Off |

| Print speed | 30-90 mm/s |

| Retraction distance | 1-3 mm |

| Retraction speed | 1800-3600 mm/min |

[ Applications]

- Prototyping and Product Development:Create robust prototypes and functional parts with excellent mechanical properties.

- Automotive Industry:Manufacture automotive components that require high strength and heat resistance.

- Aerospace Industry:Ideal for aerospace parts needing outstanding dimensional stability and mechanical strength.

- Mechanical Engineering:Perfect for producing durable mechanical components and tools.

- Consumer Goods:Suitable for making durable and heat-resistant consumer products.

- Industrial Design:Essential for creating parts that withstand demanding industrial environments.

[Why Choose Our PET-CF Filament]

- High Performance:Designed for industrial-grade strength, durability, and reliability.

- Eco-Friendly:Made from recyclable PET, supporting environmental sustainability.

- Bulk Orders Available:Ideal for wholesalers and importers looking for large quantities at competitive prices.

- Dedicated Technical Support:Comprehensive support to help you achieve optimal printing results.

- Special Pricing:Competitive rates for bulk purchases, making it cost-effective for large-scale procurement.

- Reliable Supply Chain:Consistent availability and timely delivery to support your business needs.

- Custom Solutions:Tailored solutions to meet specific business requirements, including customized packaging and formulations.

- Ease of Use:Simple to print with no need for a heated chamber, reducing complexity and energy costs.

- Versatile Applications:Suitable for a wide range of industrial and professional applications, from prototyping to final product manufacturing.

- Enhanced Print Quality:Achieve high-quality, precise prints with excellent surface finishes and mechanical properties.

[FAQ]

1. What print settings should I use for PET-CF filament? For optimal results, we recommend a print temperature of 240-260°C and a bed temperature of 70-90°C. Adjust settings based on your printer and specific needs.

2. Do I need a heated chamber to print with PET-CF filament? No, PET-CF filament does not require a heated chamber, simplifying the printing process and reducing energy consumption.

3. Can PET-CF filament be used with support materials? Yes, PET-CF filament can be used with S-PET Quick-Remove Support Material, which helps in achieving excellent surface finishes on complex models.

4. What are the main benefits of using PET-CF filament? PET-CF filament offers high strength, low moisture absorption, excellent chemical and heat resistance, and dimensional stability without warpage or shrinkage. It is ideal for industrial applications.

5. Is PET-CF filament environmentally friendly? Yes, PET-CF is made from recyclable PET, making it an eco-friendly choice for 3D printing.

6. How should I store PET-CF filament? Store PET-CF filament in a cool, dry place away from direct sunlight. Use airtight containers or resealable bags with desiccant packs to keep moisture out.

7. What are the common applications of PET-CF filament? PET-CF filament is used for prototyping, automotive parts, aerospace components, mechanical engineering, consumer goods, and industrial design due to its strength and durability.

8. How does PET-CF filament handle temperature changes during printing? PET-CF filament maintains good performance with consistent temperature settings. Avoid sudden temperature changes to ensure print quality.

9. Can I get a sample of PET-CF filament before placing a bulk order? Yes, we offer sample quantities for evaluation purposes. Contact us to request a sample and test the filament’s quality and performance.